The Evolution of MPO/MTP® Connectivity in Hyperscale Environments

In large-scale data centers, scale isn’t a nice-to-have; it’s the starting point. As networks expand to support AI workloads and edge computing, traditional duplex cabling starts to fall short. That’s where MPO/MTP® connectors stand out: high-density, multi-fiber formats that help teams deploy faster using less space.

MPO/MTP® aren’t new. Engineers have relied on them for years to simplify routing and keep fiber systems modular. What’s changed is the scale, and now, in many environments, these connectors are essential for meeting capacity and speed requirements. This post examines how MPO/MTP® became the standard in hyperscale deployments, what makes them different, and how they enable teams to build smarter fiber backbones.

What Are MPO/MTP® Connectors?

Let’s get the basics out of the way.

MPO stands for “multi-fiber push-on.” It’s a type of connector that can house 8, 12, 24, or even 48 fibers in a single plug, vastly reducing the bulk associated with traditional connectors like LC or SC. MTP®, or “mechanical transfer push-on,” is a higher-performance variant of MPO. Developed as a proprietary design, it features tighter tolerances, a removable housing, and optimized alignment for reduced insertion loss.

Both are designed for density and speed. In one click, a technician can terminate dozens of fibers, rather than manually splicing or aligning each one. In hyperscale environments where thousands of terminations are required, that’s a serious labor and time advantage.

Why Hyperscale Demands This Shift

At hyperscale, the math changes. Reducing the footprint of patch panels, minimizing congestion in ducts and trays, and accelerating install times aren’t luxuries. They’re requirements for staying on schedule and under budget.

A few drivers behind MPO/MTP® adoption at this level:

Density-per-U advantage: Standard LC panels cap out quickly. MPO-based cassettes make it easy to scale—12, 24, or even 48 fibers can fit into the same footprint.

Faster installation: MPO/MTP® patch cables and trunks arrive pre-terminated. Crews can plug in and move on—no polishing, splicing, or prep work required.

Modular migration: Upgrading from 10G to 40G or 100G? MPO/MTP® makes it easy to reuse trunks; simply swap out the correct cassette or breakout.

Hyperscale operators don’t just want these advantages—they’ve started to expect them.

Structured Cabling Impacts

MPO/MTP® adoption doesn’t just change connector choice. It affects the entire topology of your structured cabling system.

Fiber Cassettes: These devices convert MPO/MTP® trunk lines into LC breakouts for switch and server access. They’re essential for managing polarity, pinout, and connection clarity.

Breakout Harnesses: Take one MPO/MTP® and fan it out to multiple LC connections. Great for patch panels, active equipment, or when space is tight.

High-Density Trunks: Ribbon-style or micro-distribution MPO/MTP® trunks help reduce bundle diameter, improve airflow, and simplify routing in congested trays or overhead racks.

A well-planned MPO/MTP® deployment also reduces rework. Future capacity upgrades don’t require ripping out trays or running new cable. Upgrades are as simple as swapping out a cassette, patch cord, or transceiver, with no need to rerun cable.

Avoiding Common Pitfalls With MPO/MTP® Deployment

Deploying MPO/MTP® infrastructure isn’t without its quirks. Some key considerations:

Polarity Confusion: Type A, B, and C polarity options exist. Mismatching trunk cables and cassettes can result in signal loss. Stick to a documented polarity scheme from day one.

Gender Mismatches: MPO/MTP® connectors are available in both pinned (male) and unpinned (female) formats. Using the wrong mix will leave connections unmateable or unstable.

Testing Complexity: MPO/MTP® links require multi-fiber inspection and specialized testers. Ensure that your contractors have the proper tools and training to validate performance.

Good planning and better documentation can save hours during install, and years of headaches during moves, adds, and changes.

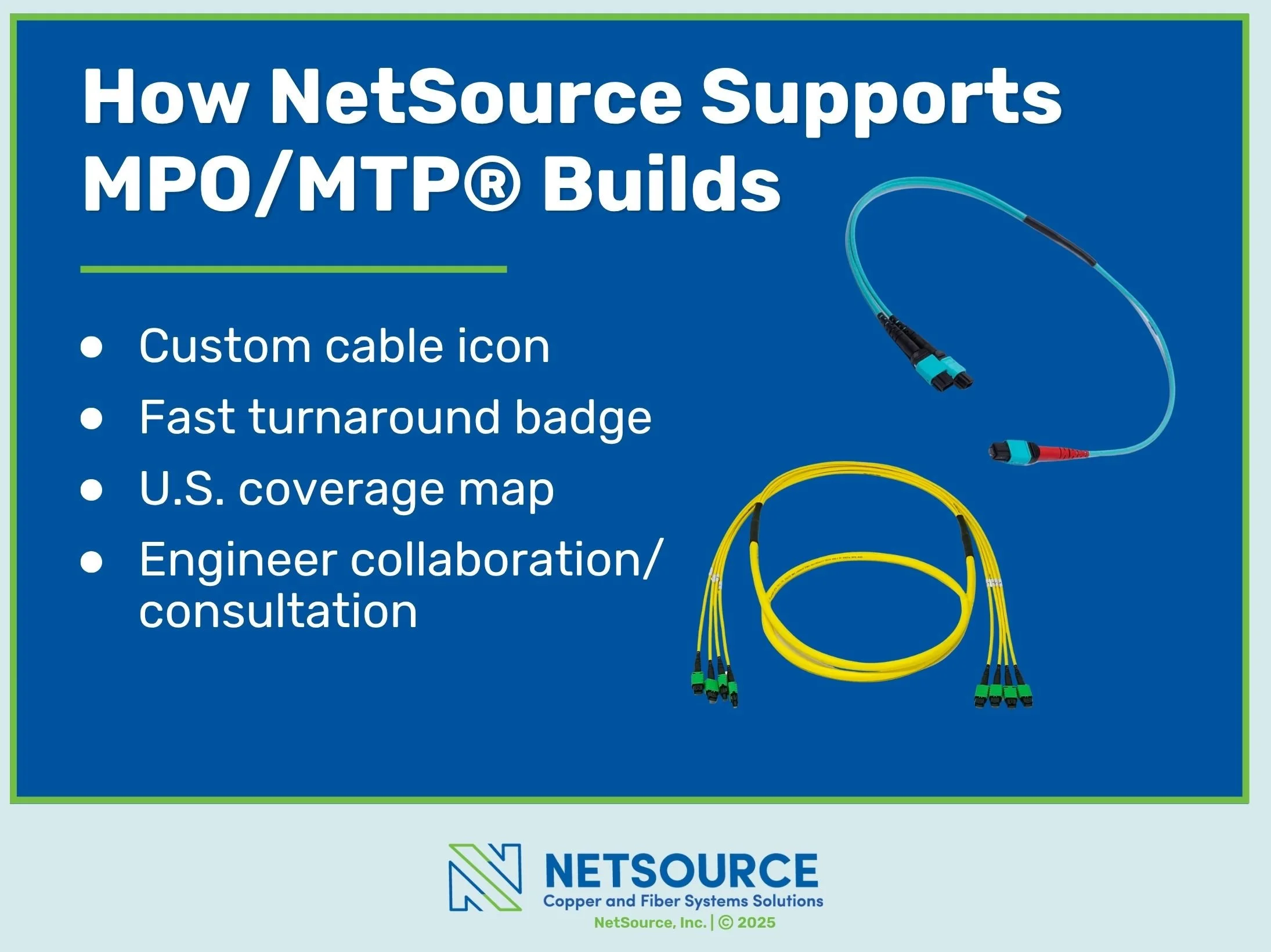

How NetSource Supports MPO-Driven Builds

NetSource works with contractors, engineers, and hyperscale clients across the U.S. to deliver MPO/MTP® infrastructure that’s spec-ready and deployment-efficient. Whether you're sourcing custom-length MPO/MTP® patch cables, high-density cassettes, or rackmount enclosures with optimized airflow, our team delivers engineered solutions without overcomplication.

We understand that timelines are tight and rackspace is expensive. That’s why our MPO/MTP® product lines are designed to minimize lead times and maximize flexibility, with no fluff and no forced bundles.

Want help with your next MPO/MTP® deployment? Our team is here to walk you through fiber counts, cassette configs, and polarity planning without a sales pitch. Contact us today!

Final Thoughts

MPO/MTP® adoption isn’t a trend. It’s a response to a physical bottleneck that traditional fiber infrastructure can’t solve. As hyperscale facilities expand, the demand for efficient, high-density connectivity will continue to grow.

NetSource can help you stay ahead of the curve with a fiber strategy built for scale.